HydraTyphon™

The HydraTyphon™ System was Developed To Deliver Improved Reliability in Difficult Environments.

THE HYDRATYPHON™ SYSTEM:

How It Works: Jet Type Perf Wash Cement with HydraTyphon™

Combining advantages of jets and cup-based systems, HydraTyphon™ challenges the boundaries of the operating envelope.

The combined benefits of both cup-based and jet-based PWC concepts improves the efficiency of the downhole hydraulic activity over any other system available, during both the washing and cementing phases of the operation.

Providing increased efficiency, HydraTyphon™ will:

- Deliver greater certainty of a successful barrier

- Expand the range of well geometries that PWC® can be applied

- Maximise the opportunity to reduce overall cost of barrier placement through

- less expensive perforating specification

- reduced spacer and cement volumes

- reduced operational duration for effective washing

The system also eliminates technical risks from lost circulation and formation damage as well as high annular cement content causing tool failure and protracted washing operations associated with conventional cup-based systems.

WHY HYDRATYPHON™?

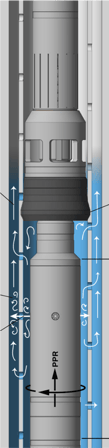

Key Features of HydraTyphon™ Jet Type Perf Wash Cement System

- Jet Nozzles for washing sequence

- Fluid Diverter – reduced cement and spacer volumes

- Bi-directional pressure relief

- Nozzle for cementing sequence

- Cement valve with check valve

- Available for all casing sizes

HydraTyphon™ PWC Tools in Operation

HydraTyphon™ delivers ‘Direct Effect’ during washing while handling potential for loss of circulating route. The new system uses string rotation during washing to ensure hole cleaning and uses ‘Enhanced Indirect Effect’ during Cementing.

The HydraTyphon™ ‘Pressure Relief Cup-system’ handles loss of circulation path and a ‘Pump-Pull & Rotate’ during cementing to maximise barrier quality. It offers lower perforating costs compared with jet-based systems for conventional PWC®.

Documentation

Download Product Report

->> Fill in your details to access in-depth insights on HydraTyphon™ and how its jet type perf wash cement technology improves PWC operations.

Talk to Our Experts About PWC Tools & Jet Type Perf Wash Cement

Have questions about PWC tools or how jet type perf wash cement technology can enhance your operations? Our specialists are ready to help.