Case Study

Perf, Wash and Cement®

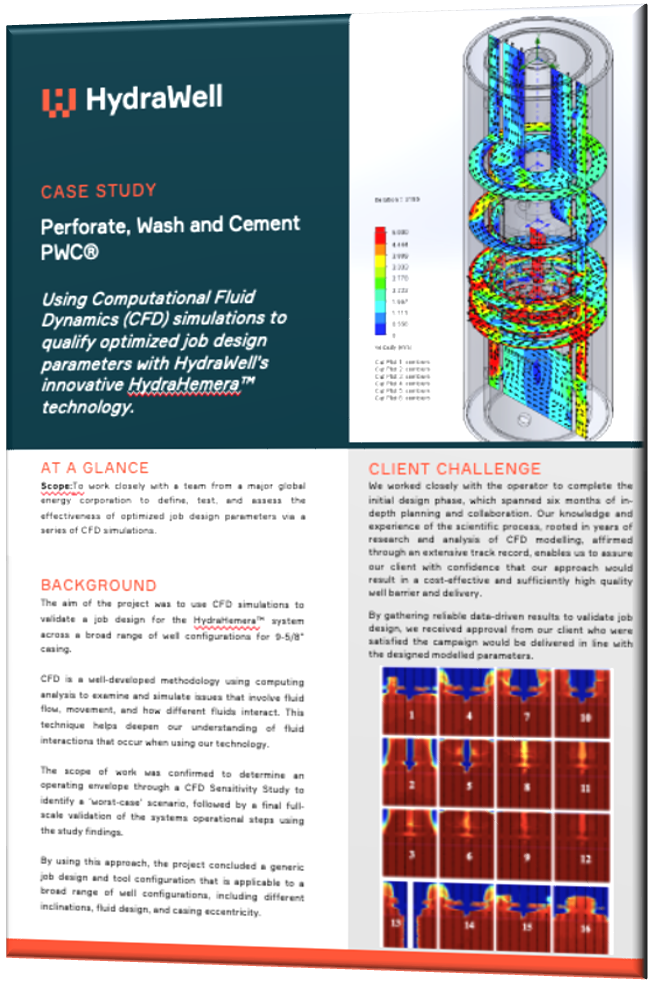

Using Computational Fluid Dynamics (CFD) simulations to qualify optimized job design parameters with HydraWell's innovative HydraHemera™ technology.

AT A GLANCE

Scope:

To work closely with a team from a major global energy corporation to define, test, and assess the effectiveness of optimized job design parameters via a series of CFD simulations.

CLIENT CHALLENGE

We worked closely with the operator to complete the initial design phase, which spanned six months of in-depth planning and collaboration. Our knowledge and experience of the scientific process, rooted in years of research and analysis of CFD modelling, affirmed through an extensive track record, enables us to assure our client with confidence that our approach would result in a cost-effective and sufficiently high quality well barrier and delivery.

By gathering reliable data-driven results to validate job design, we received approval from our client who were satisfied the campaign would be delivered in line with the designed modelled parameters.

Image 1:

Maroon (red) color indicates cement displacing the insitu fluid (blue - spacer) at various rheologies, densities etc.

BACKGROUND

The aim of the project was to use CFD simulations to validate a job design for the HydraHemera™ system across a broad range of well configurations for 9-5/8” casing.

CFD is a well-developed methodology using computing analysis to examine and simulate issues that involve fluid flow, movement, and how different fluids interact. This technique helps deepen our understanding of fluid interactions that occur when using our technology.

The scope of work was confirmed to determine an operating envelope through a CFD Sensitivity Study to identify a ‘worst-case’ scenario, followed by a final full-scale validation of the systems operational steps using the study findings.

By using this approach, the project concluded a generic job design and tool configuration that is applicable to a broad range of well configurations, including different inclinations, fluid design, and casing eccentricity.

HYDRAWELL SOLUTION

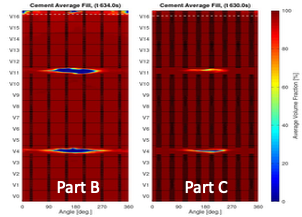

The project was divided into Part A (Sensitivity Study) and Part B (Job Design Validation) and Part C (One Extra Simulation). The objective of Part A was to determine the worst case well architecture and fluid system for implementation in Part B and included 16 simulations with varying inclination, fluid density and rheology, and eccentricity.

Once the appropriate worst-case setup was defined, this was applied to Part B with the appropriate operational parameters and fluid models.

Part B comprised 3 simulations, focused on each respective step of the operation (wash, spacer, cement).

Lastly, Part C was done to compare the findings of Part B job design study with an existing job design that uses higher performance guns and larger cement volumes.

“Integrity sits at the heart of what we do and, by taking a conservative approach, we can stand by CFD and substantiate our method of replicating the most challenging conditions and validating the job designs to apply to those conditions.

The collaboration with the client during the project was crucial in ensuring that the project incorporated correct data and assumptions, and in gaining their confidence in our capabilities.”

Markus Iuell, HydraWell Technology Development Manager

RESULTS & BENEFITS

The sensitivity study in Part A successfully concluded a worst case methodology that was implemented in Part B. The simulations in Part B revealed high performance across the entire perforated interval. Notably, as the simulations are set up as a conservative worst-case methodology for a range of applications, the effectiveness of the less challenging applications (e.g., lower well fluid density) will be even better. Part C showed minimal improvement in cement concentration compared to the optimized job design, supporting its validity. In conclusion, the optimized job design demonstrated high performance, and very little differences compared to the existing best practice, affirming the reliability of both job designs.

As well as having the reassurance of HydraWell’s CFD database with over 110 simulations, and an impressive track record of over 660 plugs deployed, the benefits of CFD technology include:

- Mastering downhole performance

- Engineering designs to perfection

- Unlimited accessibility to data

- Safe & environmentally friendly

- Cost effective alternative to testing.

Want a copy of the Case Study?

Download it here!

An introductory White Paper

Well Abandonment Planning

- The risks and how to avoid them

->> Fill in your details and get your copy now: