APPLICATIONS OF HYDRAWELL'S SYSTEMS

Permanent Plug

& Abandonment (PP&A)

Incomplete data, deteriorating well integrity, and aging construction components pose challenges in well P&A. Our solutions ensure long-term well integrity and regulatory compliance.

Slot

Recovery

Sidetracking effectively prevents re-entry into the original wellbore, optimising well utilisation during plug and abandonment operations.

Annular

Integrity

Maintaining at least two barriers between hydrocarbon-bearing formations and the environment is crucial. Our well plug and abandonment solutions restore annular integrity efficiently.

Well

Remediation

When logging images indicate a lack of cement or creeping formation, well remediation becomes essential. Our well P&A solutions restore barriers and ensure compliance.

Technologies And Solutions to Ensure Safe Well P&A

Our advanced solutions, including HemeraPoseidon™, HydraHemera™, HydraTyphon™, and HydraCT™, deliver efficient and cost-effective well plug and abandonment operations.

HemeraPoseidon™ - A Low Cost Solution For Less Complex Wells

Designed for wells with low annular cement content, the HemeraPoseidon™ system delivers efficient jet-washing and cementing in a one-trip PWC® operation. With no milling required, it ensures full-barrier placement at a lower cost while minimising operational complexity.

Learn MoreHydraHemera™ - Advanced Multi-Annuli Well plugging

Designed for wells with low annular cement content, the HemeraPoseidon™ system delivers efficient jet-washing and cementing in a one-trip PWC® operation. With no milling required, it ensures full-barrier placement at a lower cost while minimising operational complexity.

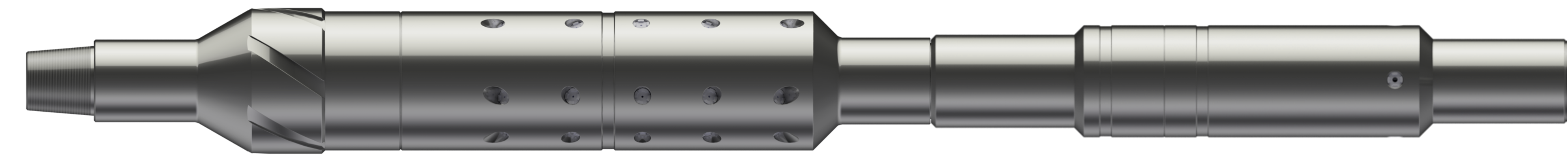

Learn MoreHydraTyphon™- Next Generation PWC for Challenging Wells

Combining the strengths of jet-based and cup-based systems, HydraTyphon™ enhances PWC® operations by reducing technical risks such as lost circulation and formation damage. It delivers a cost-effective, high-certainty cement barrier, making it ideal for challenging well environments.

Learn More

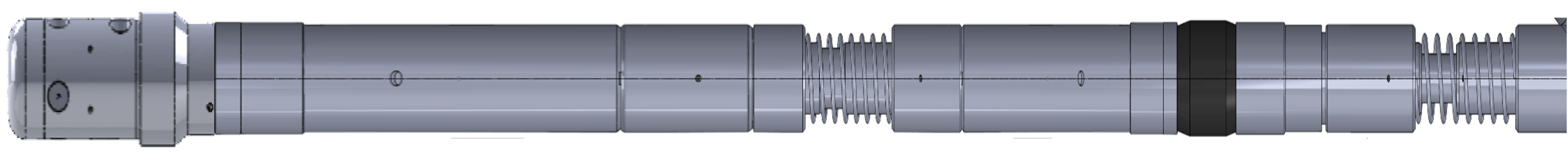

HydraCT™ - Revolutionising Rigless Well P&A

The HydraCT™ system is the first PWC® solution designed for rigless well plug and abandonment, eliminating the need for a rig or vessel. Featuring a self-rotating, jet-propulsion tool, HydraCT™ enables efficient coiled tubing operations, reducing costs by up to 60% and cutting CO₂ emissions by 80%.

Learn MoreOther Well Intervention Technologies

HydraWell offers cutting-edge technology for well integrity and plug & abandonment (P&A) operations. In addition to our core systems, we provide specialised tools designed to enhance wellbore security, optimise cementing, and streamline operations.

Annular Integrity Test Tool (AIT)

The HydraWell Annular Integrity Test Tool (AIT) allows for formation testing and cement plug setting in a single run. This tool ensures effective verification of creeping shale or formation barriers behind the casing, increasing well integrity confidence.

Learn MoreHydraKratos™

The HydraKratos™ tool establishes a secure annular base for cement, ensuring a cross-sectional barrier in HydraHemera or HydraWash operations. By expanding casing against the formation, it prevents cement slump and enhances plug stability.

Learn MoreCementing Tools

The HydraWell Jet-Cementing Valve™ revolutionises cementing operations by enabling the pump-and-pull technique, ensuring efficient cement placement across the entire plug length.

Learn MoreHydraSwivel™

The HydraSwivel™ system is designed for continuous rotation of the work string while pumping treatment fluids, optimising debris removal in high-deviation wells.

Learn MoreHYDRAWELL PROVIDES A COMPLETE PACKAGE FOR WELL PLUGGING AND ABANDONMENT

The Job Planning Process

1. Application Screening

Job design commences with a screening of the potential application to ensure our system and tooling are suitable for your needs.

Learn More2. Job Design Validation

If required, we complete validation of the job design by, for example, organising perforating gun trials and initiating Computational Fluid Dynamic modelling, as necessary.

Learn More3. Detailed Operations Procedure

We work with your engineering teams, fully participating in your planning processes and contributing to your Critical Well Reviews and pre-mobilisation operational assessments; and preparing a detailed operations procedure.

Learn More4. Logistics & Mobilisation

We then work with your logistics teams to ensure timely mobilisation to site and provide experienced field technicians to supervise the deployment and operation of our tooling packages. During operations, we provide daily operational engineering support, located in your offices as required.

Learn More5. Job Evaluation

On completion of the operation, we assess with you how well the Success Criteria for the job have been met. We compile and deliver a comprehensive End-of-Well report for our aspects of the programme, and fully contribute to your After-Action Reviews and Lessons Learnt wash-up processes. Finally (...)

Learn MoreTRACK RECORD

Case Studies

Case Story

PWC in high inclination saves weeks of rig time and operational risk

A well offshore UK has reached planned TD, but failed several contingency cement jobs. The casing sits at 81 degrees and HydraWell runs their HydraHemera jetting technology to

save the well

Case Story

PWC® jetting technology delivers four barriers in record breaking time

This client had previously installed four barriers with the conventional section milling that took more than 40 days. A close collaboration between the client and HydraWell was awarded with four plugs installed in just 8.8 days.

Case Story

Successful trial of Hydrawell´s HydraCt™ SwivelJet PWC on Coil tubing

A full scale testing of Hydrawell´s latest technology development, HydraCT™, takes place onshore Norway and immediately draws everyone´s attention to the end results! Click here to find out more!

PROVEN TECHNOLOGY

Testimonials

"I have been working with Hydrawell for the past 7 years and I have always been impressed by the forward-thinking nature of this company, the competency and dedication of its people, both onshore and offshore, the reliability of its tools and the quality of the work it performs days in and days out. This company inspires confidence"

"AkerBP used HydraWell’s Hydrahemera jetting PWC tool throughout the entire 4-year P&A campaign on Valhall DP, and with great success. Thanks to learnings kindly shared by ConocoPhillips, which pioneered the use of this technique, and to a close collaboration with Hydrawell, the time to restore barriers in a critical part of the overburden on Valhall dropped from 12 days down to 2.1, resulting in significant time and money savings."

"Impressed by their forward thinking nature"

"I am very pleased with the simplicity of the HydraHemera™ PWC® operation"

"The most robust plugging method I have ever seen"

"HydraWell´s HydraHemera™ jet-washing PWC® method saved us $15m in rig time over four wells"

"HydraWell´s PWC® technology reduced our well abandonments from 12 to 2.1 days!"

DOWNLOAD YOUR FREE WHITE PAPER

What are the common reasons for barrier failure?

- How can they be avoided?

Historically, three basic methods have been used to achieve an annular barrier. Each carries the risk of technical failure or of significant delays and increased cost beyond the forecast.

.jpg?width=1500&name=shutterstock_52704883%20(5).jpg)