Case Study

Perf, Wash and Cement®

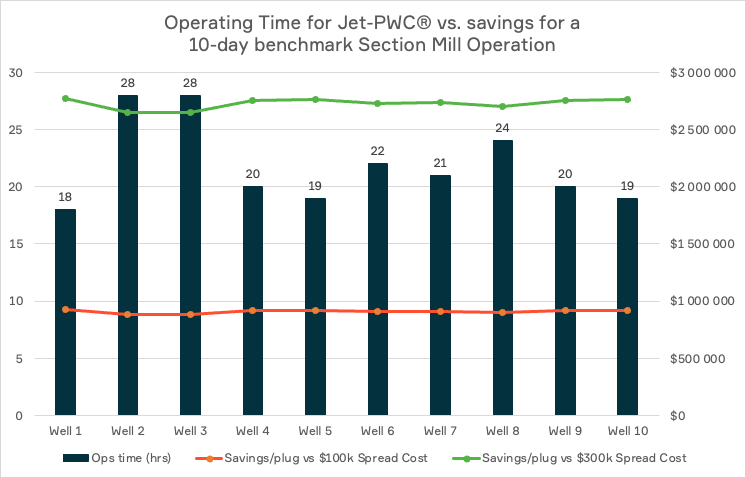

FLAWLESSLY EXECUTING PWC® OPERATIONS TO DELIVER SIGNIFICANT OPERATIONAL SAVINGS IN A 10-PLUG CAMPAIGN

Record breaking planning and operational efficiencies deliver savings of $2.7M per barrier abandonment plug

AT A GLANCE

Scope: Flawlessly executing PWC® operations to deliver significant operational savings in a 10-plug campaign

Where: Norwegian Continental Shelf

When: Q2-2022

CLIENT CHALLENGE

Our customer required an advanced solution to plug and abandon their assets in the Norwegian North Sea, across multiple annuli without the need for a section milling operation.

The campaign’s requirements were to deliver a robust, time effective and predictable campaign to reduce costs while minimising environmental impact.

BACKGROUND

Our long-term client, a major global operator, had multiple mature wells reaching the end of their life cycle and had begun a substantial P&A campaign to permanently abandon these wells. In total, 10 barrier plugs were installed as part of an abandonment campaign requiring annular remediation.

In order to comply with internal and regulatory requirements, a rock-to-rock cement barrier is required in the cap rocks above the reservoirs. Since the introduction of the PWC® (Perf Wash Cement) technology, more and more operators are looking to reduce their operational time, cost and environmental footprint associated with section milling by performing PWC® operations to establish the required rock-to-rock barriers.

HYDRAWELL SOLUTION

HydraHemera™, HydraWell’s flagship PWC® system, consists of two components, a HydraHemera™ Jetting Tool and a HydraHemera™ Cementing Tool.

The HydraHemera™ Jetting Tool was used to wash and clean out debris in the annuli behind casings. The HydraHemera™ Jetting Tool ensures optimum conditions in the casing annuli prior to placing the plugging material in the cross section. Debris, old mud, barite and old cuttings are replaced by clean mud.

The campaign focused on three key areas:

- Computational Fluid Dynamics (CFD) modelling to aid understanding of fluid interfaces and displacements to improve operational parameters and minimize time in hole.

- Improved System design to enhance PWC© delivering quality barriers.

- Quality assurance monitoring to determine job performance data and improve repeatability of efficiency improvements.

RESULTS & BENEFITS

- One trip plugging system

- No milling required

- Allows full flow when tripping in and out

- Simple design and operation

- Ideal for cleaning multiple annuli

- Available for all casing sizes

All Isolation barriers are tested and qualified using QA processes supported by CFD and previous Cement Evaluation Logging. These results have delivered:

- Savings of $2.7 million per barrier abandonment plug ≈ $27 million

- Time savings of 260 hours = 22 hours average per barrier abandonment plug

All 10 barrier plugs have been successfully installed and HydraWell is proud to have contributed to the accomplishment of this major P&A campaign to deliver a quality, sustainable solution that maximises safety and longevity.

HydraWell continues its focus on maintaining its position as the market leader in P&A applications, creating superior solutions that are carefully in step with the needs of our clients and the market.

Want a copy of the Case Study?

Download it here!

An introductory White Paper

Well Abandonment Planning

- The risks and how to avoid them

->> Fill in your details and get your copy now: