Case Study

Perforation, Wash and Cement®

ENABLE PLUGGING AVOIDING SECTION MILLING USING LEE ENERGY SYSTEMS GATOR MECHANICAL SLOT PERFORATOR

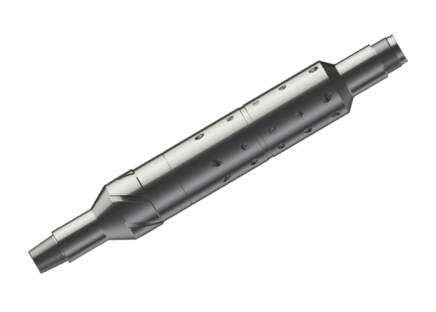

HydraHemera™ System & Gator Mechanical Perforator

AT A GLANCE

Where: Malaysia

When: 2019

Scope: Ongoing Plug & Abandonment Programme

Scope delivered on time, within budget and with no incidents

CLIENT CHALLENGE

A shallow annular barrier plug was planned at 394 mMD to address 270 psi sustained annulus pressure (SAP) in the B-annulus between 7” and 10-3/4” casings.

It was believed that the inner casing was fully decentralised and there was concern that standard explosive perforating might penetrate the low side of the outer casing.

An alternative approach was developed and delivered combining the Gator mechanical perforating technology with our Jet-based HydraHemera™ PWC® system.

BACKGROUND

Since 2016, HydraWell has been supporting clients in Malaysia with a range of plug and abandonment solutions to suit specific single and dual casing application requirements. Over 20 barrier element plugs have been successfully completed across several assets as part of an ongoing campaign. Recently, HydraWell collaborated with Lee Energy Systems to combine our technologies. Supporting a major operator, a customised solution was developed for accessing the inner annulus of concentric casing strings, without compromising the integrity of the outer casing, and avoiding section milling.

HYDRAWELL SOLUTION

HydraWell´s Generation 2 HydraHemera™ system is typically used with TCP gun systems; with a robust track record of successfully completing over 250 barrier element plugs to date. HydraWell has widely explored alternative mechanical perforating systems as a safer and more effective solution for specific PWC®applications.

The HydraHemera™ system was considered the best option for this application as its jet nozzle angles can be customized to align perfectly with the unique slots during pipe rotation, ensuring maximum jetting potential to the B-annulus.

A Tandem 6” OD Gator tool were configured 20m apart to reduce the cutting time by 50%. 67 activations with two tools created four slots per activation per tool. The tool string was rotated after each activation to create 45° slot phasing. Spacing of 0.3m per activation was tested to ensure effective washing within the B-annulus.

RESULTS & BENEFITS

The fully customised Generation 2 HydraHemera™ System combined with the Gator tool enabled PWC®operations within the 7”x 10-3/4” casing annulus without risk of compromising the outer C-annulus. A competent 40m barrier element plug between the two casings remediated the B-annulus pressure in 25% less time using our collaborative and innovative approach

Traditional methods would have involved section milling the casing, which is not only significantly more time consuming and costly; but also increases operational risk and potential damage to the outer casing. Our customised PWC® system combined with the Gator Tool delivered a safe, efficient, reliable and cost-effective plug and abandonment operation.

Want a copy of the Case Study?

Download it here!

An introductory White Paper

Well Abandonment Planning

- The risks and how to avoid them

->> Fill in your details and get your copy now: