Permanent Plug & Abandonment

Statistics from several regions in the world show that there will be 1000s of wells requiring plug and abandonment in the coming years.

The challenges of Permanent Plug & Abandonment (PP&A)

![]() All wells reach a point where the economics of production mean that they will need to be abandoned permanently so that the platform or field can be decommissioned.

All wells reach a point where the economics of production mean that they will need to be abandoned permanently so that the platform or field can be decommissioned.

Many mature fields that were drilled from the late 1970s and onwards are already reaching this point in their lifecycle. Statistics from several regions in the world show that there will be 1000s of wells to plug and abandon in the coming years.

What does this mean for the industry?

Governments and Regulatory bodies from around the world are recognising the importance of ensuring that these wells do not pollute our environment in the future. Operators are eager to ensure that these operations are done such that costs are minimised.

An ongoing challenge for the industry is permanent plug and abandonment (P&A) at the end of a well’s useful life. Challenges are caused by incomplete data, deterioration in the integrity, and condition of the construction components.

Wells that were drilled over 20 years ago, and sometimes even younger wells, present engineers and managers with a number of technical and commercial challenges. Each well drilled has a unique story, which must be understood in order to create the best plan for a successful abandonment. The collection of data needed to understand well architecture, changes in formation pressure over time, metallurgical changes to tubulars in well, cement condition in annulus, and annular pressures at wellhead, are just a few examples of the key information that needs to be collected and analysed in order to best propose a successful abandonment plan.

These issues are often manifested as a loss of integrity, or a lack of confidence, in the primary cement behind the casings. A remediation of annular cement is required to satisfy operator and regulatory requirements in a significant number of cases, in order to restore isolation between formation pressures and the surface.

What are your Plugging & Abandonment options?

There are several abandonment methods to choose from to best suit the needs of the well, ranging from section milling, cement squeeze, perf wash cement, as well as other technologies. Each comes with their own of risks and commercial consequences.

Cutting and pulling the casing

One method is cutting and pulling the casing to expose the annulus, but this can only be applied when the desired barrier is known to be above the existing cement. Even then, operations are often problematic, with corroded casing parting or debris, such as fallen-out barite causing the casing to get stuck in hole. Both instances can be very time consuming to resolve, with little predictability over solution effectiveness, additional durations and cost overruns.

Section milling

The other alternative of section milling the casing will often pose serious technical challenges, and demands a certain specification of surface equipment, further driving up costs. Swarf handling at surface poses an HSE risk and cleaning the hole and the blow out preventors (BOP) of swarf can be time consuming and problematic. Finally, the simpler approach of merely perforating a small section of the annulus and attempting to squeeze away a volume of cement, may appear attractive, but can in reality often result in failure to achieve the desired isolation, the requirement to repeat the operation a number of times, and difficulty in predicting overall durations and costs.

Perforate, Wash and Cement

Perf, Wash and Cement (PWC) offers a cost effective, predictable, and efficient alternative method of restoring a competent cement barrier behind the casing, as part of the installation of isolation barriers during permanent plug and abandonment (P&A). The method has been demonstrated to be significantly quicker than section milling and provides a higher confidence in achieving a long-term isolation barrier, compared to simple perf and squeeze techniques.

Savings achieved

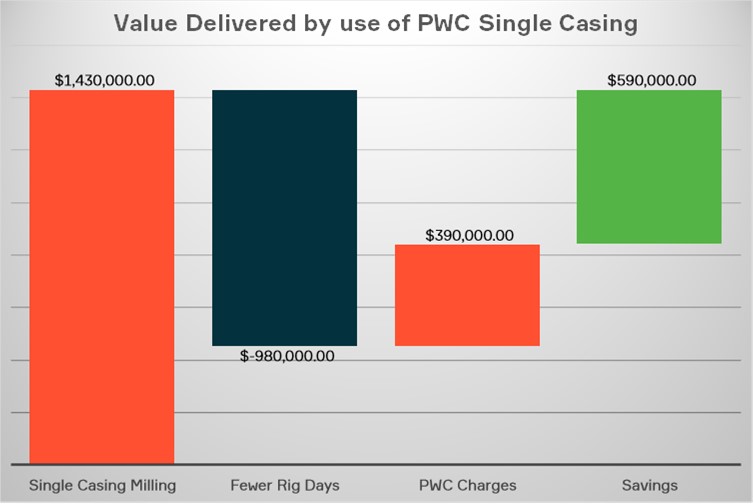

The graph highlights the cost benefits of using PWC for plug and abandonment, demonstrating savings through fewer rig days and reduced operational expenses compared to single casing milling.

How quickly costs can escalate

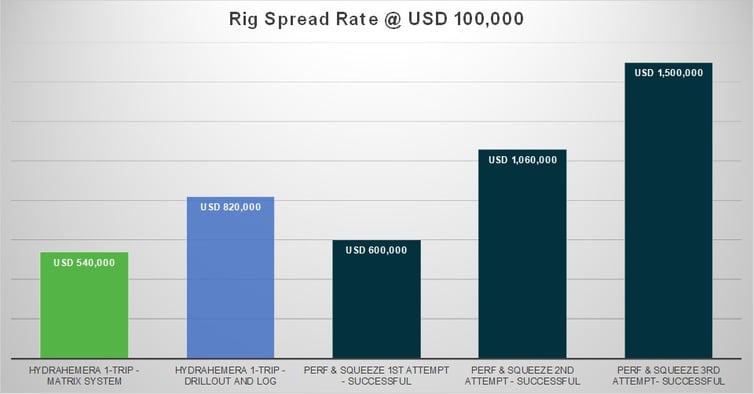

In addition, the graph below illustrates how quickly costs can escalate when using the ‘perf and squeeze’ approach and how, even at low spread costs, PWC quickly becomes the cheaper option, without the additional uncertainties of the supposedly simpler alternative.

HydraWell offers a complete service of preparatory engineering, specialist tooling provision, and operation to support plug and abandonment projects, including managing the critical interfaces with cement, fluid, and perforating gun providers, in order to integrate our services into an optimised operational procedure. Our experience has taught us that it is critical to ensure that perforation sizes provide sufficient access to the annulus and the washing programme parameters, including that flowrates, pass speeds, and jetting velocities are optimised within any constraints, such as ECD and pore pressure limits posed by the wellbore configuration. In addition, fluid choice driven by existing annular contents is key to ensuring effective cleanliness of the annulus prior to commencing cementing.

Service costs including preparatory engineering are usually of the order from USD150K per plug, but are dependent on location, tooling size, scope of supply and work scope volume.

As the inventors of PWC, and specialists in this particular area, we pride ourselves on having the best and most extensive track record in this sector of the industry, with our latest tooling design bringing the cost benefits of significantly reduced operations durations, compared to alternative versions of the technique available.

HydraWell’s PWC methodologies are routinely accepted in many regulatory environments including in UK, Norway, Netherlands, Canada and Malaysia, and are being employed by an increasing number of operators including Shell, BP, ConocoPhillips, Chevron, Petronas and Equinor with a success rate of over 98%.

Free White Paper:

What are the common reasons for failure?

- How can they be avoided?

Historically, three basic methods have been used to achieve an annular barrier. Each carries the risk of technical failure or of significant delays and increased cost beyond the forecast.

Fill in the blanks and get your copy now:

Talk to our experts

Need guidance on plugging and abandonment solutions? Use the chat pane on this page or fill out the form below to speak with our experts: