Case Study

Perf, Wash and Cement®

TEN DAYS RIG TIME SAVED COMPARED WITH CONVENTIONAL METHODS

Cure annulus pressure in dual casing application using PWC® technology

AT A GLANCE

Where: North Sea, UKCS

When: 2015

Scope: Cure annulus pressure in 7" x 9-5/8" dual casing

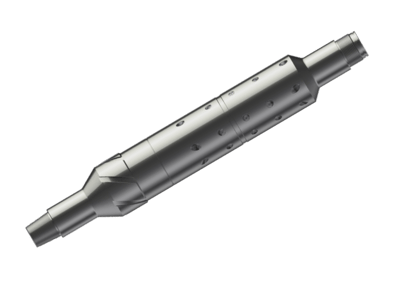

HydraHemera™ jetting technology efficiently cures annular pressure in dual casing PWC® application

CLIENT CHALLENGE

The Operator had plans to abandon the well in the Southern North Sea, but were facing challenges to efficiently place two barrier plugs in the 7" and 9-5/8" casings at the same time.

Traditionally, the solution would be to cut and pull the inner casing, or mill out the liner top packer to expose the outer casing. An operation that could prove to be time consuming not to mention costly.

Hydrawell presented our HydraHemera™ solution for a dual casing PWC® operation, and based on a robust global track record for jet-washing using PWC®, it was decided to deploy our alternative solution to establish an assured barrier in the well for P&A.

Furthermore, the well also had no annular foundation in neither annuli in the PWC® area. HydraWell’s HydraKratos™ casing expander was identified as a appropriate solution to create the annular restriction necessary to support the cement on the PWC® cement job.

BACKGROUND

A major Operator in the UKCS had previously cut and pulled the inner casing to expose the outer casing for conventional remediation methods.

Our expert well integrity team assessed well characteristics and introduced our patented PWC® jetting technology, HydraHemera™ which has the capability to cure both annuli simultaneously. HydraHemera™ is used to clean out debris in the annuli behind perforated casing and features jet nozzles which are positioned at irregular angles and engineered for optimum configuration and exit velocity to penetrate and clean thoroughly behind multiple perforated casings.

HYDRAWELL SOLUTION

First the full gun length of TCP charges, specifically designed to perforate two casing strings, together with the HydraKratosTM, were run in the well.

The identified section of the well were perforated and the HydraKratos™ casing expander detonated simultaneously, creating communication to the two annuli through the perforations, as well as providing annular support for the subsequent cement job.

HydraWell ́s patented jet-washing system, HydraHemera™, was then used to wash out debris and movable solids from both annuli. A precisely designed spacer fluid, which would water-jet the formation and casings, were jetted with high velocity into the annuli, and the subsequent cement job performed.

A specially designed cement with low fluid loss was jetted into the annuli with high energy, while the workstring was being pulled through the perforated area, leaving a rock-to-rock cement job in the abandonment area.

RESULTS & BENEFITS

Following the successful PWC® operation, the top of cement (TOC) was tagged at the expected depth, indicating a successful installation of the HydraKratosTM casing expander and cement placement. The outer casing above the 7" top of liner (TOL) was perforated and the well circulated to a lighter fluid for the upcoming negative pressure test.

The dual casing PWC® cement plug was subsequently pressure tested with about 3500 psi for 3.5 hours to confirm assured plug integrity.

The Operator and HydraWell could celebrate the first installation of the dual casing HydraHemera™ PWC® system in the UKCS, saving an estimate of 10 days rig time compared with conventional methods.

Want a copy of the Case Study?

Download it here!

An introductory White Paper

Well Abandonment Planning

- The risks and how to avoid them

->> Fill in your details and get your copy now: