Case Study

Perf, Wash and Cement®

SHALLOW LEAK REMEDIATION CAMPAIGN OFFSHORE MALAYSIA

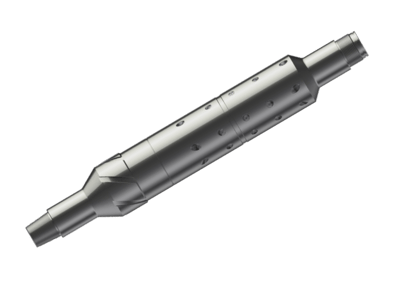

Utilizing HydraWell´s HydraHemera™ PWC® System

AT A GLANCE

Where: Offshore Peninsular Malaysia

When: 2020

Scope: 10-well P&A offshore campaign

Shallow surface casing leak remediation to address annular integrity issues including sustained annular pressure (SAP) inside the B-annulus.

CLIENT CHALLENGE

Annular pressure began building up several days after a 60m element had been set inside 7” x 10-3/4” casing from 420m.

The element had been accepted earlier by the Client based on drill pipe tag of 10k lbs and 1000 psi pressure test, but its integrity was now being questioned. Had the PWC® plug failed? In some instances we have seen residual gas trapped within the annular fill that will eventually deplete from extended venting. The third possibility was shallow gas influx via an outer casing leak.

There was no evidence of plug failure based on job execution, post job verification, and history of success in the other wells. The pressure trend was monitored over several days while alternating extended venting and pressure build-up, but the pressure trend did not change. The gas detector readings showed it was not hydrocarbon and consisted of 20% O2 and 1000 ppm CO. Review of the open hole drilling log from 1983 indicated a possible shallow gas pocket across this section. A subsequent leak detection log run indicated a possible outer casing leak around 200 m.

BACKGROUND

HydraWell has been delivering PWC® scopes in Malaysia since 2016, with 33 successful operations to date. This 10 well P&A campaign saw severe corrosion in the surface casing below the wellhead. Some wells required epoxy resin reinforcement prior to rigless intervention with a hydraulic workover rig.

12 PWC® barrier plugs were installed to address annular integrity issues, including sustained annular pressure and SAP inside the B-annulus. This was a complex scope due to risk of surface handling and penetrating outer surface casing during sustained annular pressure remediation.

HYDRAWELL SOLUTION

The final conclusion was a leak from the outer casing caused by corrosive, shallow non-hydrocarbon gas. Ideally, the 7” casing could be cut above the plug and pulled to facilitate remediation of the outer casing; however the primary cement was nearly to surface. It was decided to conduct another PWC® from the top of the previous plug to remediate this leak. A 60m plug was set from 210m-150mMD.

Special consideration had to be taken to avoid penetrating the outer casing and to avoid surface handling risk due to shallow perforating tubing shock.

A customised jet-based PWC® system compatible with mechanical perforating system was selected to meet this challenge. A high volume of cement debris was observed during washing was consistent with the CBL. There was also some interesting gravel collected that appears to be formation breakthrough from the outer casing. The stabilized B-annulus pressure was about 95 psi prior to the job and was not bled off throughout the job. The pressure reduced to 5 psi during washing and was replaced with 14.5 ppg cement. The plug integrity was later confirmed by drill pipe tag 10k lbs and 1000 psi pressure test. The annulus pressure 10psi was bled off and remained at zero for 24 hr and Client accepted.

RESULTS & BENEFITS

A holistic design approach combined with effective collaboration with onshore design team and communication with offshore execution team ensured all procedures were followed.

HydraWell’s integrated design approach addressed unplanned well conditions and system tests prior to operations determined optimum operating parameters.

As a result the customer´s PWC® operations were successfully performed inside outer casing without risk of compromise and remediate unexpected well conditions.

The customer saved time over costly section milling and was able to eliminate sustained annulus pressure from multiple sources to achieve abandonment objectives.

Want a copy of the Case Study?

Download it here!

An introductory White Paper

Well Abandonment Planning

- The risks and how to avoid them

->> Fill in your details and get your copy now: