Case Study

Perf, Wash and Cement®

SINGLE AND DUAL CASING PWC® OPERATIONS FROM A HYDRAULIC WORKOVER UNIT (HWO)

Successful Onshore PWC® campaign

AT A GLANCE

Where: Onshore Continental Europe

When: 2020

Scope: Flawlessly executing PWC® operations from HWO Unit

Permanent rock-to-rock barriers installed without section milling

CLIENT CHALLENGE

Several of our client wells have in-sufficiently cemented annuli across the cap rock formations. The governing bodies require a rock-to-rock cement barrier across an impermeable cap rock as close to the reservoir as practically possible. In order to minimise cost, the client wished to use HWO units which are not readily adapted to section milling due to torque and RPM limitations.

Limitations on speed of drill pipe connection make-up, and tripping speed running ‘singles’, also increases operational time negating the potential cost savings from using an HWO. In addition, avoiding section milling reduces environmental impact by eliminating swarf and mud disposal, therefore reducing emissions with a shorter scope duration.

BACKGROUND

Our client, a major Oil & Gas Operator, has a growing portfolio of mature wells reaching the end of their lifecycle and a substantial P&A campaign to permanently abandon these wells has begun. Several wells being plugged and abandoned require annular remediation and in order to comply with internal and regulatory requirements, a rock-to-rock cement barrier is needed in the cap rocks above the reservoirs.

Since the introduction of our PWC® technology, many operators are looking to reduce their operational time, cost and environmental footprint associated with section milling by performing PWC® operations to establish the required rock-to-rock barriers.

HYDRAWELL SOLUTION

Three wells were identified as PWC® candidates, all with two casing strings in the target PWC® interval.

The first two wells were deemed to have competent barriers in place outside the second 9-5/8” casing string. Therefore, only the inner, 7” x 9-5/8”, annulus required remediation to establish a rock-to-rock barrier.

The third well required cement to be placed in both annuli and had sustained annulus pressure of ±5 bar in the 9-5/8” x 13-3/8” C- annulus.

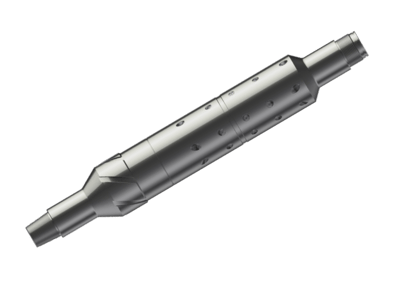

60m single casing x casing HydraHemera™ PWC® barriers were placed in the 7” x 9-5/8” annuli in the first two wells. For the third well, the dual casing HydraHemera™ system were run to place a cement barrier in both the 7” x 9-5/8” annulus and in the 9-5/8” x 12-1/4” open hole annulus in one operation.

For the single casing applications, together with our client, the HydraWell team used the TCP system that would also penetrate the outer 9-5/8” casing. The verified barrier behind the 9-5/8” casing was sufficiently competent to potentially temporarily lose its integrity in the PWC® interval during execution of the washing operation. The perforation channels were filled with cement and barrier integrity restored when the PWC® operation was successfully completed.

RESULTS & BENEFITS

In close collaboration with four Oil and Gas Service Providers, Hydrawell flawlessly installed the first two PWC® plugs in the 7” x 9-5/8” annulus across the salt formation caprock using the HydraHemera™ single casing PWC® 1-trip system.

The wells were perforated over 60m intervals and subsequently washed and cemented. Any perforation channels created in the outer casing strings were cemented in the same process, re-establishing the competent barrier in the 9-5/8” x 13-3/8” annulus.

For the third well, the dual casing PWC® operation was successfully executed and the sustained C-annulus pressure was cured.

All three wells have since been completely abandoned successfully. HydraWell is proud to have been key to the positive start of a long P&A campaign and strengthen the collaborative relationships between all the parties involved.

Want a copy of the Case Study?

Download it here!

An introductory White Paper

Well Abandonment Planning

- The risks and how to avoid them

->> Fill in your details and get your copy now: